silicone rubber sheet for glass lamination vacuuming

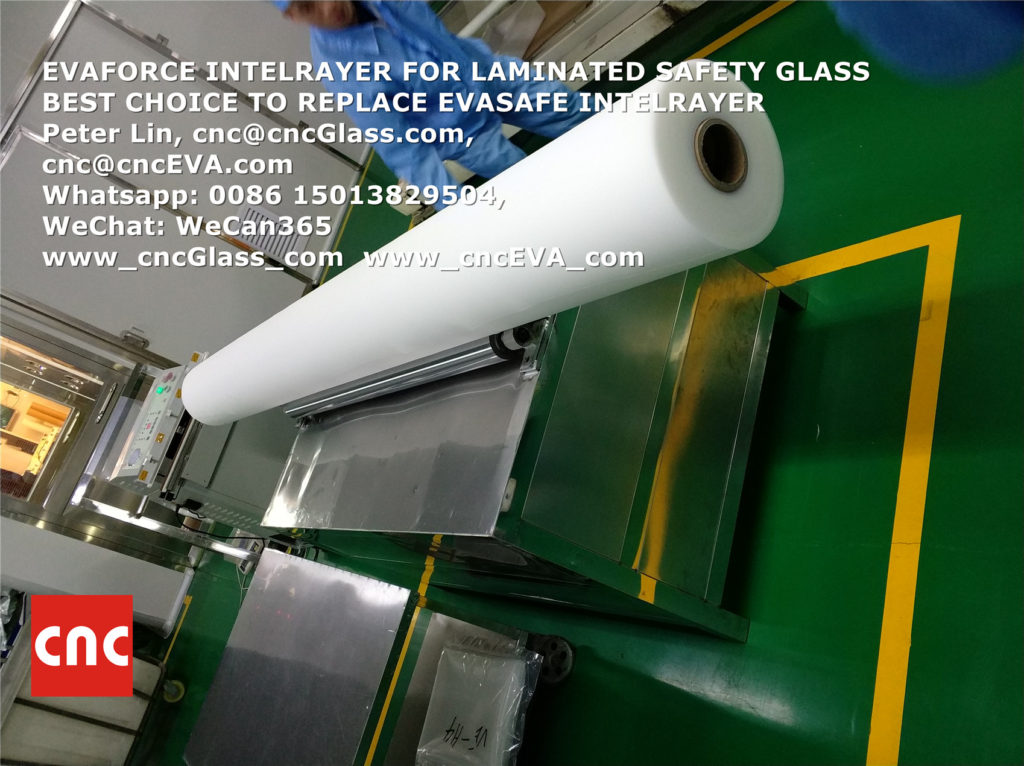

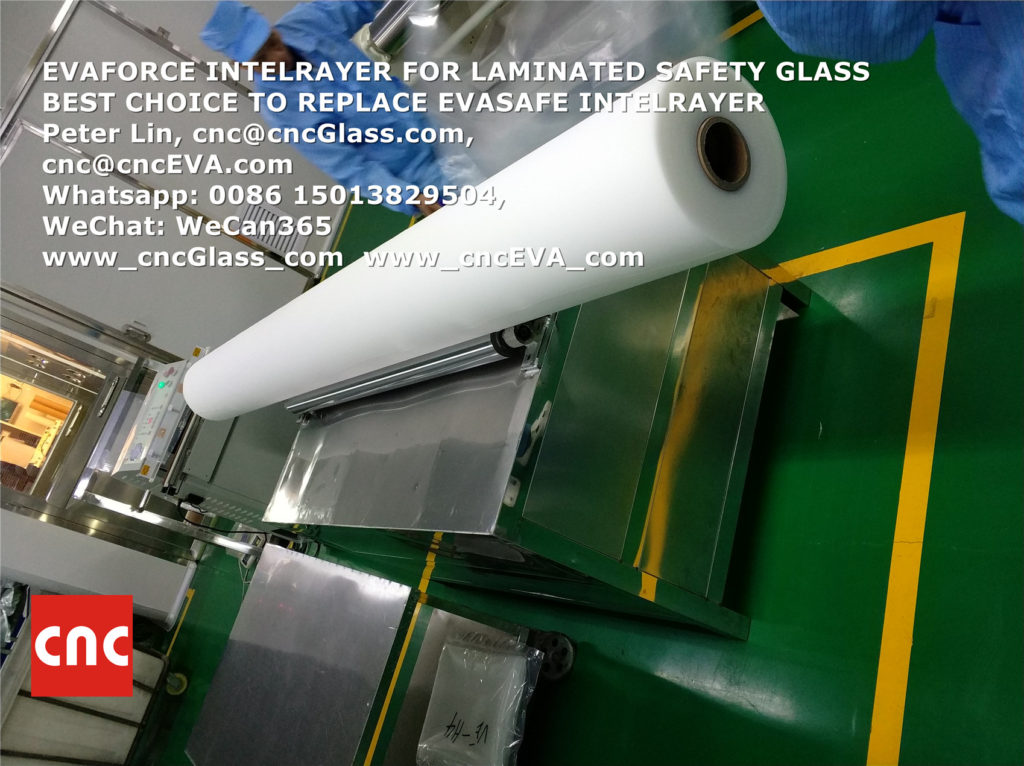

EVAFORCE INTERLAYER FOR LAMINATED SAFETY GLASS

BEST CHOICE TO REPLACE EVASAFE INTERLAYER

Peter Lin, [email protected],

Whatsapp: 0086 15013829504,

WeChat: WeCan365

www_cncGlass_com www_cncEVA_com

Due to their molecular structures and arrangements they are amorphous polymer materials, and that is why both of them have excellent optical properties, and the reason of why they have been used to laminate glasses for Architectural applications.

But it is not just on matters of their optical properties why they can be used in Architectural applications, it is also because of their mechanical properties. Their elastic modulus properties give them the needed properties to dilute the glass-glass dimensional and thermal dilatation tensions when in operation under different weathering environments.

Peter Lin, [email protected],

Whatsapp: 0086 15013829504,

WeChat: WeCan365

www_cncGlass_com www_cncEVA_com

For architectural constructions security is a critical parameter that always should be warranted regardless of the type of glass laminate. That is why, for example to construct balustrade walls, it is not allowed to be built them with just a single piece of glass. Legislation force to use laminated glass systems to insure that when by any reason there is a breakage of one of the glasses, the other one will be able to sustain the small glass pieces adhered to its surface. Safety is first and legislation protect users, by requiring the use of laminated glasses. The process of lamination is looking for implementing of the security element between glasses. The main objectives of the non-glass element is to provide flexibility to the structure an also a good adhesion of the glass in case of glass breakage.

Either the PVB or the EVA are good materials for such a purpose. The differences between them show up in terms of their process-ability or the final mechanical properties (dilatation coefficients, young modulus, elastic modulus) of the product depending their final application and use. There is where the chemical and physical properties of both materials are important. The above mentioned differences in chemical composition and structure between EVA and PVB allow us the Chemist, Polymer Scientist and Chemical Engineers, play with the raw materials to convert and transform them into specific products with differential and desired performances. Even though it is true that we can manipulate these materials and “drive” them to behave in some extension along our desired performances, for such type of applications where safety is really important, any kind of “gummy materials” we might think to use, they are forced to reach some minimum value properties to fulfil the required security standards.

Having said that, it is important to mention that not all EVA or PVB materials are the same. Under the acronyms of EVA and PVB many different performance products might be considered. It is important to distinguish all of them by looking at their PDS (Product Data Sheets) that manufacturers need to provide. This is an important information to know by the glass lamination companies in order to produce the highest quality lamination glass products according their lamination equipment and processes. But this is not all, at this point here it is important to point out that the relevant properties of the laminated product are the final ones, we mean the ones that any laminate product should fulfil after these materials are laminated and are verified by norms by qualified certification institutes.

Peter Lin, [email protected],

Whatsapp: 0086 15013829504,

WeChat: WeCan365

www_cncGlass_com www_cncEVA_com

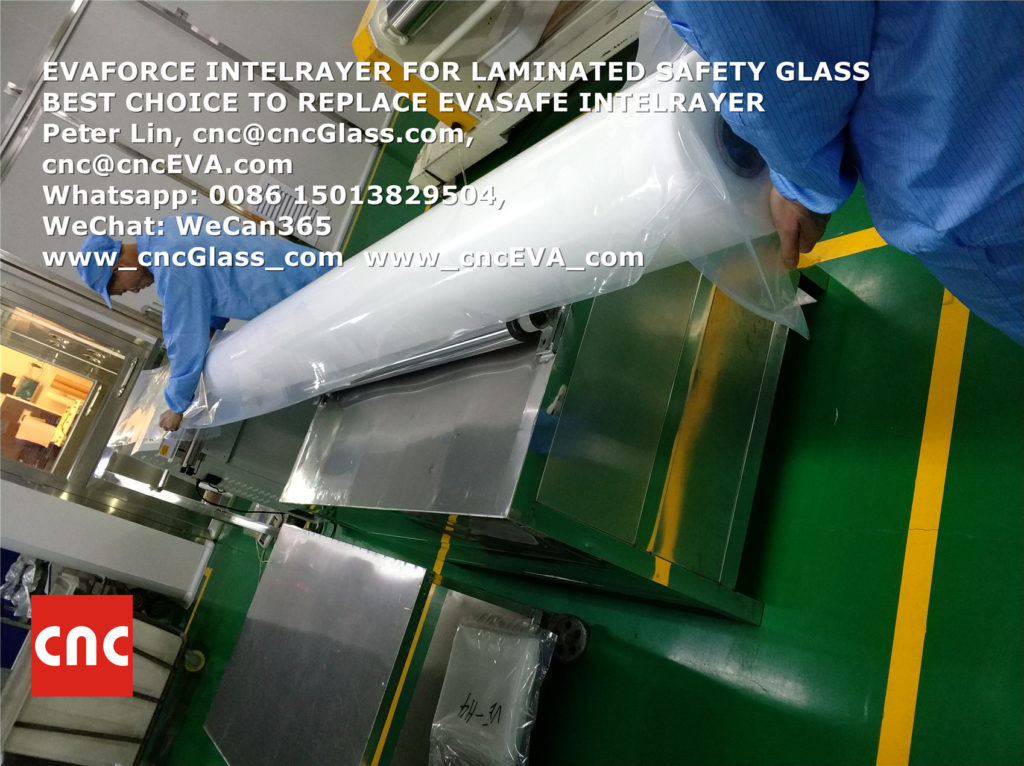

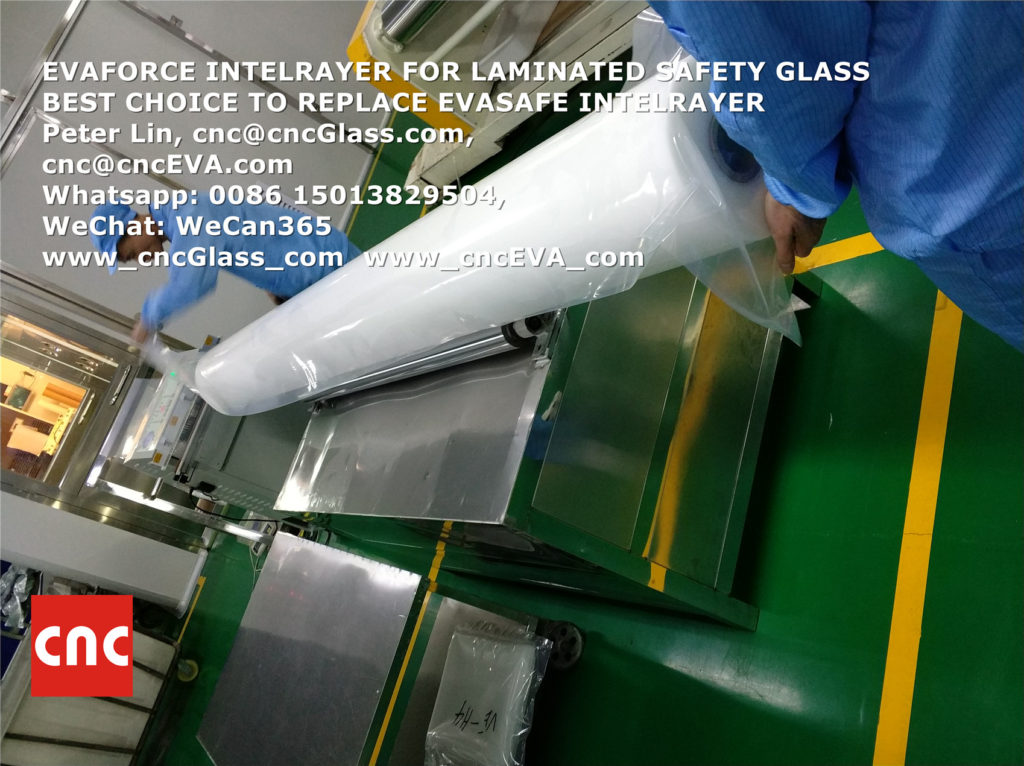

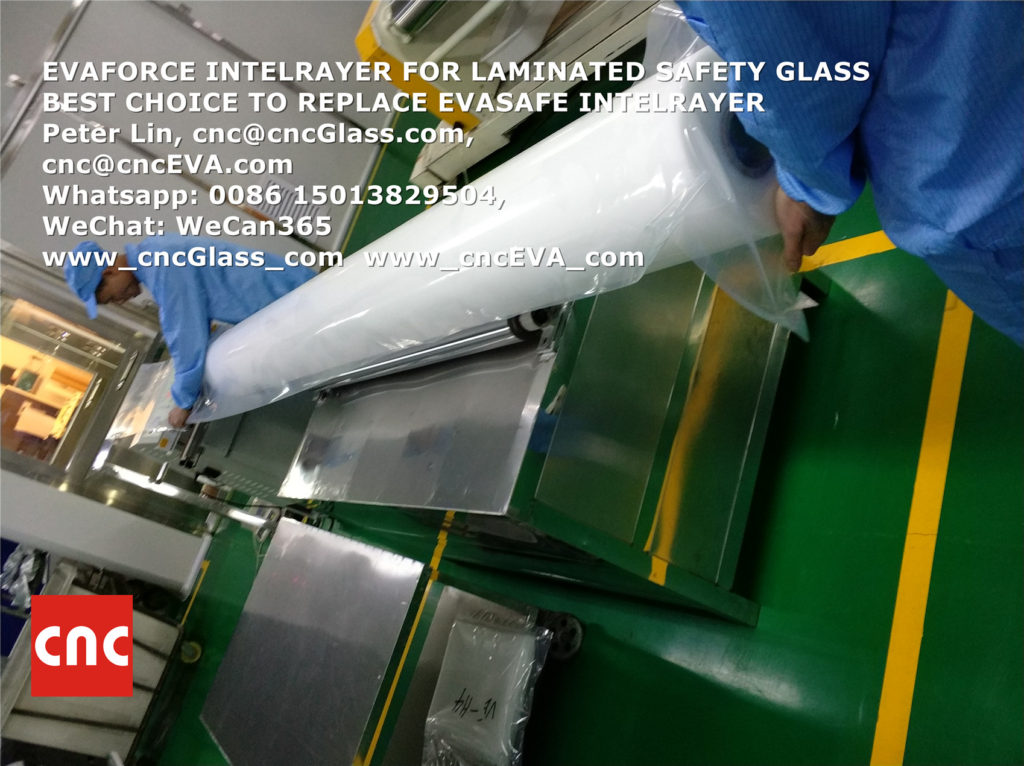

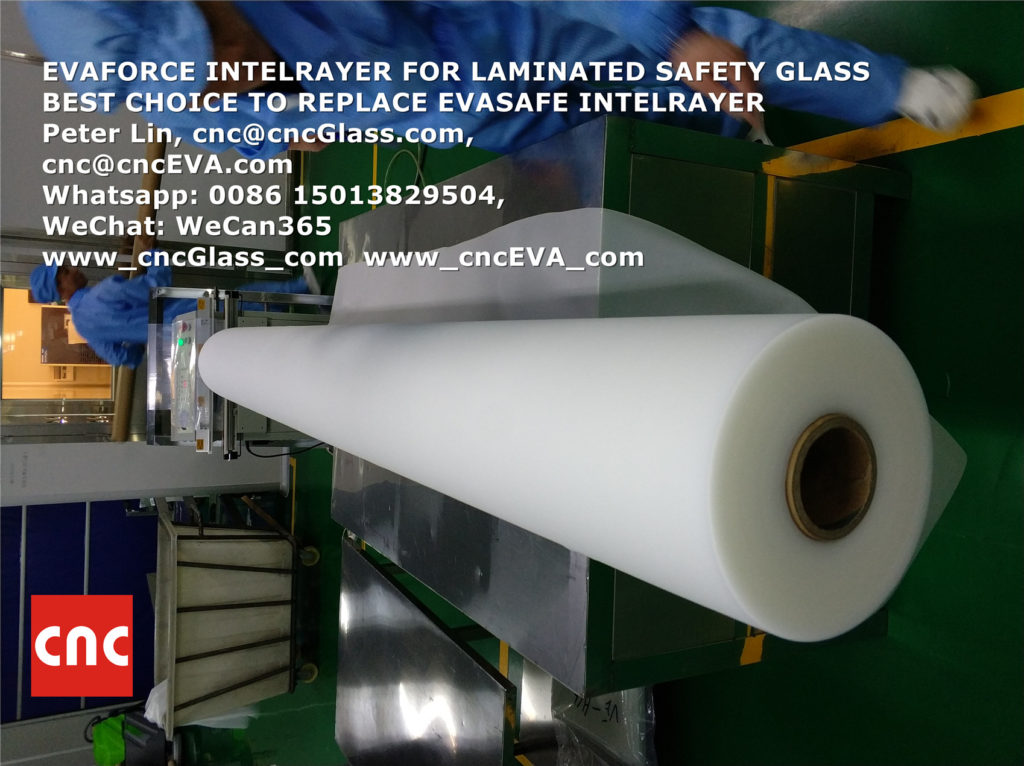

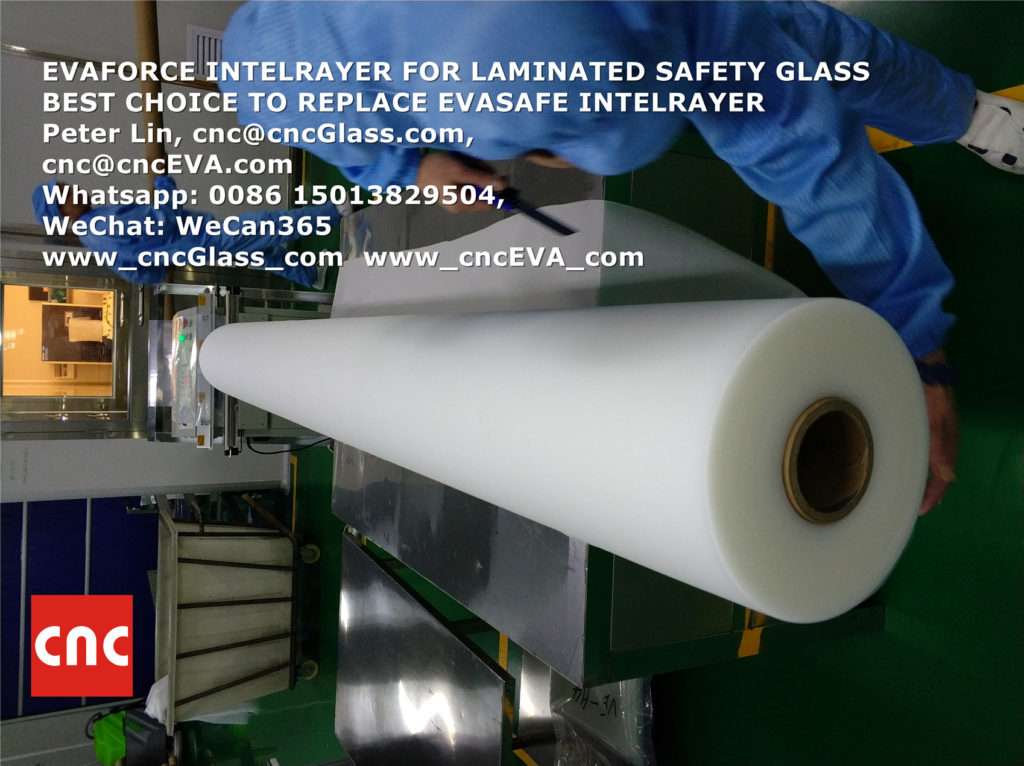

EVAFORCE INTERLAYER FOR LAMINATED SAFETY GLASS

BEST CHOICE TO REPLACE EVASAFE INTERLAYER

Peter Lin, [email protected],

Whatsapp: 0086 15013829504,

WeChat: WeCan365

www_cncGlass_com www_cncEVA_com

Due to their molecular structures and arrangements they are amorphous polymer materials, and that is why both of them have excellent optical properties, and the reason of why they have been used to laminate glasses for Architectural applications.

But it is not just on matters of their optical properties why they can be used in Architectural applications, it is also because of their mechanical properties. Their elastic modulus properties give them the needed properties to dilute the glass-glass dimensional and thermal dilatation tensions when in operation under different weathering environments.

Peter Lin, [email protected],

Whatsapp: 0086 15013829504,

WeChat: WeCan365

www_cncGlass_com www_cncEVA_com

For architectural constructions security is a critical parameter that always should be warranted regardless of the type of glass laminate. That is why, for example to construct balustrade walls, it is not allowed to be built them with just a single piece of glass. Legislation force to use laminated glass systems to insure that when by any reason there is a breakage of one of the glasses, the other one will be able to sustain the small glass pieces adhered to its surface. Safety is first and legislation protect users, by requiring the use of laminated glasses. The process of lamination is looking for implementing of the security element between glasses. The main objectives of the non-glass element is to provide flexibility to the structure an also a good adhesion of the glass in case of glass breakage.

Either the PVB or the EVA are good materials for such a purpose. The differences between them show up in terms of their process-ability or the final mechanical properties (dilatation coefficients, young modulus, elastic modulus) of the product depending their final application and use. There is where the chemical and physical properties of both materials are important. The above mentioned differences in chemical composition and structure between EVA and PVB allow us the Chemist, Polymer Scientist and Chemical Engineers, play with the raw materials to convert and transform them into specific products with differential and desired performances. Even though it is true that we can manipulate these materials and “drive” them to behave in some extension along our desired performances, for such type of applications where safety is really important, any kind of “gummy materials” we might think to use, they are forced to reach some minimum value properties to fulfil the required security standards.

Having said that, it is important to mention that not all EVA or PVB materials are the same. Under the acronyms of EVA and PVB many different performance products might be considered. It is important to distinguish all of them by looking at their PDS (Product Data Sheets) that manufacturers need to provide. This is an important information to know by the glass lamination companies in order to produce the highest quality lamination glass products according their lamination equipment and processes. But this is not all, at this point here it is important to point out that the relevant properties of the laminated product are the final ones, we mean the ones that any laminate product should fulfil after these materials are laminated and are verified by norms by qualified certification institutes.

Peter Lin, [email protected],

Whatsapp: 0086 15013829504,

WeChat: WeCan365

www_cncGlass_com www_cncEVA_com

![]() High temperature masking tape

High temperature masking tape

Polyester green tape

[email protected] www.cncGlass.com

[email protected] www.cncnext.com

Whatsapp: 0086 15013829504

Wechat: WeCan365

Peter Lin